High Quality Sterile Indicator

What is a sterility indicator for? How to use it correctly?

How it works

What is a sterility indicator for?

Classes and types of indicators for sterilization control

Applications

Recommendations for use

Medical instruments, equipment and containers at food industry enterprises are all subject to sterilization. The process destroys all biological pathogens, bacteria, spores and viruses that are on the surface of objects.

It is impossible to assess the quality of sterilization “by eye”. There is always a risk that for some reason sterilization has not reached the final stage or certain requirements have not been met. That’s what sterilization parameters control indicators are for.

How it works

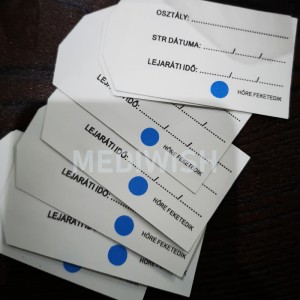

Chemical indicators are strips of film and heat-resistant paper that show how correctly sterilization has been carried out. The parameters that are subject to mandatory control depend on which processing method is used:

steam sterilization – steam quality, temperature, duration of exposure, completeness of air removal;

air sterilization – temperature and exposure;

chemical sterilization with ethylene oxide or antiseptic solutions – the concentration of the sterilizing agent, temperature, exposure time.

Each paper strip has two colored marks. One of them performs the function of an indicator, changing the shade after processing. The second is the standard of the sterility indicator, with which the result is compared.

What is a sterility indicator for?

The purpose of chemical indicators is to determine whether the parameters of a particular sterilization process have been met. It is worth noting that by themselves they do not give an idea of how effective the processing was. It is possible to speak objectively about the degree of purity of sterilized products only after bacteriological tests and analysis of microbiological cultures.

Therefore, the main thing for which indicators are used in medicine and industry is express control of compliance with the requirements for the processing process itself.

The advantages of this verification method are obvious:

instant receipt of information, without waiting for the results of laboratory tests;

no need to use additional incubators to check the accuracy of the results;

the possibility of checking the absorbed dose of radiation.

By helping to detect problems in a timely manner, chemical indicators minimize the risks associated with the use of poorly sterilized products.

Classes and types of indicators for sterilization control

Chemical indicators of sterility are divided into classes depending on which conditions cause the reaction and change in color of the marker. There are six of them:

Process indicators. Show the very fact of sterilization (carried out or not). The key function is to quickly sort those objects that have already been processed from the rest.

Bowie-Dick tests. More advanced type of indicators for sterilization control. They do not control the observance of exact parameters, but they allow you to evaluate the quality of the steam and how efficiently air is removed from the chamber.

Single parameter. They can respond to changes in temperature or pressure. Substances such as benzoic acid, sucrose, hydroquinone are used in this class of sterilization control indicators.

Multiparametric. Changes in thermo-temporal and barometric parameters are recorded. Color change occurs only if the treatment lasted at least 75% of the required time, and other standards are fully met.

Integrators. They react if all basic parameters have reached the values necessary for the death of pathogenic microorganisms.

Emulators. Record all critical variables of special sterilization regimens. The color changes when the duration of the processing cycle is observed at least 95%, and the remaining parameters fully comply with the established requirements.

Proper use of chemical indicators of sterility at the enterprise allows the personnel to draw conclusions about the suitability of products for use almost immediately after processing is completed. The test strips themselves can act as documentary evidence that the processes and technologies used are up to standard.

Applications

Paper indicators of different classes are in demand wherever instruments and equipment are sterilized:

medical institutions;

industrial and research laboratories;

food industry enterprises;

blood transfusion stations;

beauty salons, hairdressing and manicure rooms.

For dry ovens sterility indicators of classes 1-3 are suitable. If more complex types of equipment are used for processing (for example, autoclaves), it is recommended to choose indicators of class 4 and above.

Recommendations for use

Indicators must be used for each processing. Speaking about how to use the indicator correctly, it is important to remember that they need to be placed in hard-to-reach places of medical products – for example, inside a flask or in the center of a package.

To make it convenient to remove the strip after processing is completed, the indicator is glued onto a piece of writing paper measuring 2×15 cm. If, after sterilization, the color of the marker differs markedly from the reference, the processing is repeated.

Records on the results of chemical control are made in the “Journal of control of the operation of sterilizers” (form 257 / y). The test strips themselves are also pasted into the appropriate column as documentary confirmation of the results, and are stored at the enterprise for at least 12 months.

Store the indicators in the manufacturer’s packaging at a temperature of +5 to +40°C and a relative humidity of not more than 80%.